Commentary, information and resources related to green manufacturing, sustainable manufacturing and sustainability in the US and abroad. Based on information from a variety of sources (web to print) and including technical information from researchers in the field as well as researchers at the University of California in the Laboratory for Manufacturing and Sustainability (LMAS - lmas.berkeley.edu).

We are saddened to report that Professor Dornfeld passed away in March, 2016. If you enjoyed his blog, please consider making a contribution to The David A. Dornfeld Graduate Fellowship fund at UC-Berkeley that has been established in his memory to support high-achieving graduate students in the Department of Mechanical Engineering.

Sunday, November 27, 2011

Tools of the trade, Part 3

Maps and directions

We continue our discussion of the the OECD (Organization for Economic Co-operation and Development) Sustainable Manufacturing Toolkit and related items. In case you've missed the past two posting you can find details on the toolkit in and on line Start-up Guide.

Last time we looked at the seven defined steps from priority setting to performance indicators and normalization factors - factors that relate the level of performance to the individual product (piece, weight, volume) or to sales volume, etc. These factors could be based on production quantities in number, sales volume, hours worked, levels of service provided ("over one billion hamburgers served"!) or product lifetime.

The tool kit also discusses how to prioritize areas of improvement that can be focused on. One can use a degree of impact to assist with prioritization. For example, improving air quality may result in a significant environmental impact as well as business related impacts. "High" impact for the environment is defined as resulting in "significant damage or enhancement to the general environment" and likely to be "of great concern to stakeholders." This level of impact for the business side of the equation is defined a having "significant ramifications for business and reputation with potential for substantial losses or gains."

Medium impact is a lesser - moderate - view of above and low impact is minimal damage or enhancement of environment and ramifications for business and reputation.

One interesting visualization approach suggested is the "priority matrix" for showing, graphically, the positive or negative impacts in terms of key performance indicators. The matrix shows the relative impact in terms of both environmental and business effects/results. On the environmental impact axis contributors include: energy efficiency, air and water quality, use of toxic materials, use of renewable materials, greenhouse gas emissions and product impact. On the business axis contributors include: sales, cost, licence to operate, disruptions to operation and reputation/brand.

The illustration below, from OECD, shows the bands of high priority issues (dark) to low priority issues (light) in this matrix with a data point for each impact or, I assume, interaction between business and environment.

The impacts with the highest potential for improvement/damage are the first priority.

This type of visualization has been proposed by others as well and can be a powerful illustrative tool for showing present circumstances (in terms of environmental or business conditions) as well as plotting changes.

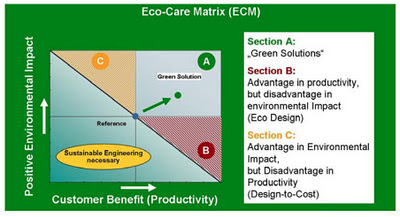

An excellent example of this is the Siemens "Eco-care Matrix". The eco-care matrix has along the x-axis the business or customer benefit and along the y-axis the environmental benefit. A presentation by the head of Siemens Industry Solutions Division last year explained that the concept is to allow the assessment of the environmentally compatibility and cost effectiveness of anything from a single product to a complete industrial system or plant. The figure below, from Siemens, illustrates the concept.

The reference dot in the center describes the environmental performance and economical customer benefit of one or more green solutions compared to a defined reference solution (usually an existing product of system.) The environmental performance is measured using typical life cycle analysis (LCA) outputs and, for example, can use the results of a LCA tool such as GaBi. The reference point, according to a published paper by Wegener (see reference below) is based on a system or product that "should deliver nearly the same function or service to the customer as the considered green solution. Only if both product systems under examination have the same function using of course different process technologies and product designs, their environmental impacts can be related to

the same functional unit."

The "new solution" is plotted on the matrix compared to the reference. Only if the trajectory improves both environmental and business benefits is the solution considered an overall improvement.

The economic benefit is determined using standard business accounting practices comparing the costs/benefits of the two alternatives.

For a detailed discussion of this approach, including an example and references, see the paper titled "Improving Energy Efficiency in Industrial Solutions - Walk the Talk" by Dieter Wegener et al from the Riso International Energy Conference in 2011.

A basic example is shown in a web posting from Siemens for a type of gearless AC motors used in dragline excavators — vehicles that pull a bucket freely suspended on a boom across earth or rocks in order to extract materials in large scale mining operations. The high efficiency of these motors makes the excavator 22 percent more environmentally compatible than the DC motor that serves as the reference, while reducing electricity costs by 22 percent.

Reading through the Siemens Eco-care Matrix methodology one can't help but notice strong similarities to the OECD toolkit approach. Concerns are on prioritization, normalization and the use of standardized metrics in the analysis to yield a realistic basis for decision making.

The OECD Toolkit also offers a number of case studies applying the methodology.

A logical process based on measurable impacts/performance related to realistic business outcomes and aided by a methodology for prioritization and progress tracking - all form a solid methodology for greening manufacturing.

Finally, I am participating in an Autodesk sponsored GreenBiz webinar on "Design Technology as a Sustainability Strategy for Manufacturers" on December 13th 2011 at 1PM EST. I will be joined in this webcast by Patrick Coulter, Chief Operating Officer, Granta Design, and Sarah Krasley, Product Manager, Sustainability, Autodesk. Joel Makower, Executive Editor at GreenBiz Group, will moderate the panel. You can find more info, and register for this free event, at the following GreenBiz link. Hope to "see" you there!

Monday, November 14, 2011

Tools of the trade, Part 2

Still turning!

In the last posting we began digging into the OECD (Organization for Economic Co-operation and Development) Sustainable Manufacturing Toolkit. The toolkit can help companies the their business approach to be more viable, socially responsible and get the most out of greening opportunities and features a set of 18 key performance indicators (KPI) to measure and improve the environmental performance of manufacturing facilities.

You can find details on line: a Start-up Guide and a Web Portal with additional technical guidance, data tools and useful links.

The discussion in the toolkit elaborates on the relationships between manufacturing and the environment from the perspective of:

- inputs ( materials and things used in the product you make or in elements that go into the product you make),

- operations (process and systems that take the inputs and convert them into products, including facilities, transport of inputs and products, business travel, employee commuting, and other overhead), and

- products (including their use and end of life disposition)

But, the toolkit indicators mentioned above do not include the impact from commuting staff and logistics to transport inputs or products shown in the figure, but include the impact from business travel. This can be included in other ways.

The tool kit suggests "seven steps" to utilize the KPI's as illustrated in the circle image below from OECD. See the last posting for the list of KPI's.

The process starts with setting priorities and moves through measurement and improvement. Two significant steps are #2, select useful performance indicators (and determining what data needs to be collected), and step #3, measure the inputs used in production (this helps to identify how the materials and components used in production processes and systems influence environmental performance.)

Following this are the improvement steps.

An important part of the analysis is the selection of normalization factors - that is, relating the level of performance to the individual product (piece, weight, volume) or to sales volume, etc. The tool kit illustrates a number of different factors you can select to normalize the performance, including:

- Number, weight or units of products produced in the facility.

- Sales or value added in the facility.

- Person-hours worked in the facility.

- Units of function or level of services to be provided by the products produced in the facility.

- Lifetime of the products produced in the facility.

In our very early discussion of green metrics we introduced normalization factors, for example green house gas emission per capita, or area, or country. These are similar. You want to relate the impact to some measurable unit that makes sense in your business. Then determining where you are, and tracking where you have been or are going, is much easier.

The tool kit also discusses how to prioritize areas of improvement to focus on. It suggests a matrix showing the relative impact in terms of both environmental and business effects/results. This has been proposed by others as well and can be a powerful illustrative tool for plotting changes.

We'll go on to that in the next posting.

Finally, my lab has been looking into social metrics of sustainability and how they intersect engineering and manufacturing decision making and activities. There will be more to come on this for sure. But, in the meantime, one of the researchers found an interesting web-based survey from the Fair Trade Fund, Inc. to estimate your "slavery footprint."

Starting from the question "how many slaves work for you?" (!) it guides you through a set of questions starting with your gender through your living standard, eating habits (including exceptional interest in what kind of nuts you eat), jewels you own, electronics you have, sports you play (and at each stage mentioning the conditions some folks in various parts of the world work in to provide these - for example, did you know that "In China, soccer ball manufacturers will work up to 21 hours in a day, for a month straight" - according to the survey?), and, of course, your closet (and reminding me that "1.4 million children have been forced to work in Uzbek cotton fields. There are fewer children in the entire New York City public school system"!).

At the end it tells you "how many slaves [are] working for [me]" based on their data and on my consumption patterns and, then, the typical supply chains and sources for these goods and materials.

I have no idea how accurate this website is and I do not endorse its data base or determinations. But, it is very illuminating, and sobering if at least true to some extent. It told me I have 48 slaves working for me. (It looks like my closet is the culprit!) Even if it is off by 50% that is still 24 slaves - nothing I am comfortable with.

Try it - it is sobering. And if you are a manufacturer with supply chains or materials sources from some of the suspect regions this can be a cause of concern and risk.

One last thing - LMAS has set up a Twitter page! You can follow the comments and observations of the researchers in LMAS with the "OTHER LINKS ON GREEN MANUFACTURING" on this page on the right. I will add my comments from time to time as well. We promise not to overwhelm you with our "insights"!

In the last posting we began digging into the OECD (Organization for Economic Co-operation and Development) Sustainable Manufacturing Toolkit. The toolkit can help companies the their business approach to be more viable, socially responsible and get the most out of greening opportunities and features a set of 18 key performance indicators (KPI) to measure and improve the environmental performance of manufacturing facilities.

You can find details on line: a Start-up Guide and a Web Portal with additional technical guidance, data tools and useful links.

The discussion in the toolkit elaborates on the relationships between manufacturing and the environment from the perspective of:

- inputs ( materials and things used in the product you make or in elements that go into the product you make),

- operations (process and systems that take the inputs and convert them into products, including facilities, transport of inputs and products, business travel, employee commuting, and other overhead), and

- products (including their use and end of life disposition)

But, the toolkit indicators mentioned above do not include the impact from commuting staff and logistics to transport inputs or products shown in the figure, but include the impact from business travel. This can be included in other ways.

The tool kit suggests "seven steps" to utilize the KPI's as illustrated in the circle image below from OECD. See the last posting for the list of KPI's.

The process starts with setting priorities and moves through measurement and improvement. Two significant steps are #2, select useful performance indicators (and determining what data needs to be collected), and step #3, measure the inputs used in production (this helps to identify how the materials and components used in production processes and systems influence environmental performance.)

Following this are the improvement steps.

An important part of the analysis is the selection of normalization factors - that is, relating the level of performance to the individual product (piece, weight, volume) or to sales volume, etc. The tool kit illustrates a number of different factors you can select to normalize the performance, including:

- Number, weight or units of products produced in the facility.

- Sales or value added in the facility.

- Person-hours worked in the facility.

- Units of function or level of services to be provided by the products produced in the facility.

- Lifetime of the products produced in the facility.

In our very early discussion of green metrics we introduced normalization factors, for example green house gas emission per capita, or area, or country. These are similar. You want to relate the impact to some measurable unit that makes sense in your business. Then determining where you are, and tracking where you have been or are going, is much easier.

The tool kit also discusses how to prioritize areas of improvement to focus on. It suggests a matrix showing the relative impact in terms of both environmental and business effects/results. This has been proposed by others as well and can be a powerful illustrative tool for plotting changes.

We'll go on to that in the next posting.

Finally, my lab has been looking into social metrics of sustainability and how they intersect engineering and manufacturing decision making and activities. There will be more to come on this for sure. But, in the meantime, one of the researchers found an interesting web-based survey from the Fair Trade Fund, Inc. to estimate your "slavery footprint."

Starting from the question "how many slaves work for you?" (!) it guides you through a set of questions starting with your gender through your living standard, eating habits (including exceptional interest in what kind of nuts you eat), jewels you own, electronics you have, sports you play (and at each stage mentioning the conditions some folks in various parts of the world work in to provide these - for example, did you know that "In China, soccer ball manufacturers will work up to 21 hours in a day, for a month straight" - according to the survey?), and, of course, your closet (and reminding me that "1.4 million children have been forced to work in Uzbek cotton fields. There are fewer children in the entire New York City public school system"!).

At the end it tells you "how many slaves [are] working for [me]" based on their data and on my consumption patterns and, then, the typical supply chains and sources for these goods and materials.

I have no idea how accurate this website is and I do not endorse its data base or determinations. But, it is very illuminating, and sobering if at least true to some extent. It told me I have 48 slaves working for me. (It looks like my closet is the culprit!) Even if it is off by 50% that is still 24 slaves - nothing I am comfortable with.

Try it - it is sobering. And if you are a manufacturer with supply chains or materials sources from some of the suspect regions this can be a cause of concern and risk.

One last thing - LMAS has set up a Twitter page! You can follow the comments and observations of the researchers in LMAS with the "OTHER LINKS ON GREEN MANUFACTURING" on this page on the right. I will add my comments from time to time as well. We promise not to overwhelm you with our "insights"!

Subscribe to:

Posts (Atom)