Commentary, information and resources related to green manufacturing, sustainable manufacturing and sustainability in the US and abroad. Based on information from a variety of sources (web to print) and including technical information from researchers in the field as well as researchers at the University of California in the Laboratory for Manufacturing and Sustainability (LMAS - lmas.berkeley.edu).

Monday, April 26, 2010

Earth Day and Carbon Offset Credits

I promised more tech talk in the end of last week's posting. This will be "tech-lite"!

Earth day has come and gone and, judging by the amount of coverage all things green are getting (from consumer products to industrial and enterprise practice), things are looking up for good ol' Mother Earth. Of course, we all know someone who got stuck in Europe by the big belch of a volcano in Iceland ... so we will never be quite as clever about all this as we think.

We just completed a calculation of our lab's carbon footprint and will now buy carbon offsets for that amount as part of our efforts to "incentivize" ourselves to reduce our footprint. Of course, the actual control we have in our lab, comprised of some rooms in the first floor of a six story building (with one big on-off switch for the HVAC that we cannot control) sitting on a campus with one large power meter measuring the campus energy, seems small on first glance. But, we do travel, use lights and machinery, buy consumables for experiments, so we are not without some ability to change our impact.

In the August 10th, 2009 posting (see http://green-manufacturing.blogspot.com/2009/08/whats-your-footprint.html) we had an extensive discussion about footprints and some on-line tools for calculating them. Our strategy for calculating our lab's footprint is more analytical.

We presented a scenario of how we do these calculations and why at a recent campus open house for the public and I will summarize this here. Josh Chien, one of the researchers in the lab, worked this up. (I gave a link to a you-tube video of his presentation with all the details in the last posting - see http://lmas.berkeley.edu/public/?p=1266; narrated by his girlfriend!). I will be quick to acknowledge that our lab (a few thousand square feet of space, some 20 researchers (and their travel), a couple of nice machine tools and other processing hardware, computers, instruments, espresso machine, desks and furniture, computer projector, etc.) is not Wal-Mart. But it is probably close to a large number of small businesses. This is more like the calculation a "department" in a large corporation would do. We did not include our share of the general campus infrastructure we use in our daily operation.

We define carbon footprint as a collective measure of one’s environmental impact, in particular, direct and indirect greenhouse gases (GHG) produced from creating and sustaining human activity; typically, represented as global warming potential (GWP) with units of metric tonnes (or kg) of carbon dioxide equivalent (MTCO2e).

We calculated this using a hybrid economic input-output life cycle analysis (EIOLCA). I discussed this approach in a recent posting (http://green-manufacturing.blogspot.com/2010/01/low-hanging-fruit-4.html) and we applied it to a manufacturing example in the last of the greening the supply chain postings two weeks ago.

The hybrid-LCA approach was used to determine our carbon footprint with respect to four sectors:

- embodied energy (lab equipment and food)

- electrical energy (direct emissions from our local utility, PG&E)

- steam energy (lab heating and hot water)

- transportation (commuting to lab and business trips)

The EIOLCA GWP database by Carnegie Mellon University is a source for data that represents U.S. average, see www.eiolca.net for an excellent discussion and data source.

Now for some details.

Embodied energy refers to the energy and resources consumed during the raw material extraction, manufacturing and transportation phase of a product - the output is indirect GHG emissions measured in MTCO2e, or embedded GWP for an item. This can be calculated as: item cost ($year) × EIOLCAGWP (MTCO2e/$year) = GWPembd (MTCO2e). For example, for the desks in our lab

Electrical energy refers to the power consumption of a product during its use phase - the output is indirect GHG emissions measured in MTCO2e. This can be calculated as: power (kWh) × Costelec ($/kWh) × EIOLCAGWP (MTCO2e/$) = GWPelec (MTCO2e)

or, if the mix of your local utility is known,

power (kWh) × GWPPG&E (kgCO2e/kWh) = GWPelec (MTCO2e). For example,

Steam energy refers to the energy required to generate steam for heating and producing hot water - the output is indirect GHG emissions measured in MTCO2e. We can calculate this for our building and then, lacking any more specific data, apportion it to our lab based on our percentage of the floor space in the building.

Finally, transportation refers to the energy required for a transportation mode - the output is direct GHG emissions measured in MTCO2e. This is calculated, for land travel (none of us commute by boat!), as mpg × distance (miles) × emission (GWP/mile) × days/year = GWPtrans (MTCO2e).

We use the following conversion factors for land-based transportation (including BART, our local subway):

- gasoline: 8.9 kgCO2e/gal

- diesel: 10.2 kgCO2e/gal

- BART: 0.06 kgCO2e/mi

For air travel, usually to and from conferences and meetings, we use an online calculator from Climatecare (see http://www.jpmorganclimatecare.com/). to estimate the impact of travel. It considers length of travel, etc. Everyone lists their business and commuting related travel for the lab calculation. Not surprisingly ... I am the biggest contributor to this one!

Now for some results. Our total GWP for 2009: 175.43 MTCO2e is comprised of the following amounts from the four components:

- embodied energy: 120.70 MTCO2e

- electrical energy: 15.50 MTCO2e

- steam energy: 2.31 MTCO2e

- transportation: 36.92 MTCO2e

The importance of "location" is brought home in the computation of our electrical energy consumption and it's CO2 equivalent. The figure below shows a comparison of our impact using our "local" utility (with a very renewable mix of energy sources) with the equivalent data from the EIOLCA website referenced above. This EIOLCA data reflects the US average. PG&E uses much cleaner and more renewable energy than the U.S. average.

Clearly, it is a big advantage, in our case, to use the more accurate local data. And, once again, it shows the importance of location in your supply chain impact calculation.

Now, what to do about this? We have chosen to purchase carbon offsets from Carbonfund.org, a leader in providing carbon offsets (www.carbonfund.org), to "offset" out the GHG impact of our lab. Any individual, business or organization can purchase carbon credits, equal to their carbon footprint, thus offsetting their carbon impact and becoming certified carbon neutral.

Carbon credits can be used to help fund renewable energy, reducing overall energy demand, reforestation & avoided deforestation and many more. The assumption, and you need to verify this, is that the money you spend for the credits you purchase goes to the intended purpose of carbon reduction or capture in the amount you paid. This is, to me, an "unregulated" market so one wants to be sure the organization one purchases the credits from has some track record.

in 2007, LMAS became the first UC Berkeley lab to become carbon neutral and offset 415 MTCO2e with carbonfund.org. We missed last year. Our footprint of 175 MTCO2e this year is substantially reduced from the first year we did the calculation. This is due to, primarily, the initial footprint of all the embedded existing hardware, furniture (ie non-consummables) in the lab.

What about the cost? There are many helpful websites comparing the cost, and benefits, of different sources of credits. One good one is http://www.ecobusinesslinks.com/carbon_offset_wind_credits_carbon_reduction.htm. On that site you'll see that, for Carbonfund.org, the cost of a one metric ton of CO2 equivalent credit is $10.00. And, importantly, you can see what the funds are used for - in this case Renewables, Efficiency, Reforestation. It also indicates and certification the organization has for its "product".

In the case of Carbonfund, they are certified or verified by Environmental Resources Trust, Climate Community and Biodiversity Standards, Chicago Climate Exchange, UNFCCC JI. The site gives links to the websites of these organizations. Other categories of carbon credit sources, some for which they could not find certification or verification are shown as well. It also says that businesses can often get a "volume discount" or carbon offset credits!

So, whether or not you decide to do this for your organization, it is an interesting exercise. The Carbonfund website has a built in calculator but part of the "fun" is doing it yourself.

I feel better already!

Sunday, April 18, 2010

Green Bits

We've spent the last posting discussing supply chains from a manufacturing and green aspect. Following on these discussions, I wanted to mention an upcoming webinar on "Supply Chain Carbon Mapping in Four Industries" to be presented by Climate Earth on Tuesday, April 20th, at 11 am PDT/ 2 pm EDT (1 hour). There is no cost for the seminar and you can register at https://www1.gotomeeting.com/register/346073969 or go to http://www.climateearth.com/. There is an archived webinar on "Carbon Efficient Supply Chains" at http://www.climateearth.com/webinar_2009_11_18.shtml. The four industries covered are food processing, packaged goods, manufacturing, and services

A recent survey by McKinsey on "How companies manage sustainability" caught my eye. You need to register to download the full report (but it is free) at http://www.mckinseyquarterly.com/How_companies_manage_sustainability_McKinsey_Global_Survey_results__2558. The survey was done in February 2010 covering almost 2000 executives in a wide range of industries and locations. Among the results shown is a table showing how companies keep track of the "value created by sustainability programs." Although no detail is given on the programs the results support some of our earlier musings on why green (or sustainable) matters.

The items tracked are:

- reputation building (over half agree this is a key metric)

- growth opportunities

- cost savings

- risk avoidance

- employee attraction, retention and productivity

- customer loyalty

The study also identified "proactive" executives (surprisingly only about 6% say "sustainability is a top-three priority" in their agendas with the associated actions associated with it.) These executives tend to be much more proactive in seeking ways to enhance the sustainability of their organizations. They list the following statistic - "84 percent of respondents at engaged companies are aware of whether or not their companies measure their carbon footprint" and, more importantly, these engaged companies are more likely, with respect to their supply chain and customers, to be keeping track of "relevant sustainability indicators such as waste, energy and water use, and labor standards."

Now to some green technology wedges!

I participated in and spoke at a conference earlier this month in Nashville sponsored by AMT and NCMS - two organizations well engaged with the manufacturing industry in the US. It was called the 2010 AMT/NCMS Manufacturing Technology Forum and the focus was on green manufacturing. You can see some details at http://www.amtonline.org/article_display.cfm?article_id=160249§ion_id=268.

I presented an overview of issues and opportunities in green manufacturing (many of them discussed in these postings) and spoke again about the concepts of the technology wedges. I first introduced these in the September 15, 2009 blog (see http://green-manufacturing.blogspot.com/2009/09/green-manufacturing-technology-wedges.html). I related this concept to specific approaches to reducing energy consumption in manufacturing with examples from machine tool design and operation.

One of the other speakers, Scott Hibbard, Vice President of Technology at Bosch Rexroth in Illinois. Besides being a very sharp engineer in the drive and controller business we both have roots in Wisconsin. He discussed drive & control technology to increase energy efficiency and spoke of many bits of enabling technology for some of the exact applications I have been thinking about in the past. Things such as energy recovery from machines during changeover or down cycles, reduction in "tare" energy for machines, reduction (or increase in efficiency) of process related energy, etc.

He showed the required "what percentage of US consumption my particular area is responsible for" slide derived from Department of Energy data but this time reflecting motors and drives. Turns out about 70% of industrial energy consumption falls in this category. He further broke that category down to specific applications of these motors and drives to include pumps (hydraulic and others) 27%, compressed air systems 18% material movement (also known as motion control - this is used in machine tools, robots, conveyors, etc.) 30%, for example.

Just to make sure we are all on the same page let's define a few terms. Drives (often adjustable speed) is usually a combination of hardware and software that powering and adjusting the operating speed of a mechanical load. This is often an electric motor and a speed controller or power controller. The "drive" often refers to just the controller. In machine tools these motors can be synchronous or induction, AC, DC (brushed or brushless), or step motors and can be rotary or linear motion providers. Try our old friend Wikipedia for a quick source of info. The combination of a motor and drive with some higher level control hardware/software makes up one axis of motion of a modern numerically controlled machine tool as we've discussed them before.

Scott identified 4 major areas for energy savings and, incidentally, increasing productivity:

- Efficient components (use products and systems with optimized efficiencies)

- Energy on demand (only use energy when needed; recall our tare vs process energy discussion a few blogs back)

- energy recovery (store and reuse or sell back excess energy; and we had referred to energy recovery from the spindle of a machine tool also)

- Energy conscious system design (include energy consumption and efficiency in the design of the machine or system from the start)

One of his examples showed 20% regenerative power from "machinery braking" and the return of that power to the electricity utility. "Energy exchange" between motor and generator drive modes is also a possibility with 15% recovery.

One neat example relied on storing of excessive energy not required during short-time operation and intermittent operation by means of hydraulic accumulators and accumulator charging circuits. Without getting into the details, accumulators in hydraulic systems are pressure storage reservoirs containing a hydraulic fluid (considered to be incompressible - meaning doesn't compress under load - most liquids are like this) that is held under pressure by an external source such as a spring, compressed gas (gases do compress under load!), weights or other mechanisms. Using an accumulator, the pump on the hydraulic system need not be as large to accommodate the load variations and, they can store energy! Combine this with a variable speed pump which can use up to 65% less energy thanks to utilization of stand-by mode when idle-running and speed reduction with slower motions.

Scott showed this technology applied to a hydraulic press. These presses are used for forming large sheets of metal as in automotive components like fender, hoods, etc as well as a variety of formed metal products. Think of a giant hydraulic cylinder with a forming tool set (punch and die) and sheets of metal.

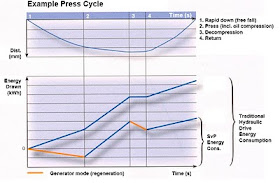

The figure below, from Scott's presentation, shows a typical energy use cycle for a hydraulic press. The top figure shows the press cycle with a rapid down motion, the press forming section,

decompression and return of the cylinder (and top die) to top position. The bottom portion compares the energy used over time with the conventional and variable speed pump drive with regeneration. There is a dramatic savings. In addition, since motors generate heat, etc. there will be a reduced building environmental load as well.

We've gotten a little heavy on the tech talk this time. But, it is an excellent example of the potential in operation of our manufacturing machinery to apply wedges that, in combination with a lot of other machine improvements, make big differences. A typical automotive manufacturing press shop will have dozens of these presses operating 24/7 (when production is good of course) and the savings realized on one machine multiplied by all adds up.

More tech stuff next time!

And, for youtube fans, we've posted two videos on our lab website from a recent open house called "Cal Day": one is on how we calculate the carbon footprint of our laboratory and another on a recent experiment showing side by side energy consumption and a milling experiment in the lab. Both are accessible at http://lmas.berkeley.edu/public/?p=1266. Enjoy!

Saturday, April 10, 2010

Greening the supply chain, Part 4

Last of a series

I ended the last supply chain discussion remarking that keeping track of the bits and pieces of a supply chain (resources, impacts, locations, suppliers, transit routes, etc.) is not trivial but that, as we become better at tracking these, the metrics, software tools, analytical methodologies and, even, simple rules of thumb, can be developed and used to get a better picture of where we are and what progress we are making.

I know from a number of advertisements and tech magazine articles that the major players (think SAP, Oracle and ERP and PLM applications - I am sure there are many more) are already well established in the "bean counting" and can provide much of the data needed to get us started at the enterprise level and supply chain at some level.

In an earlier example in this series, we focused on a fictitious auto production operation with stamping, assembly and sales in different parts of the workd. We saw the sensitivity to energy source impact variations in different locations. Last time we dug a bit deeper into these variations and what they mean in supply chain impact determination.

In this posting, I'd like to present a more practical example based on real data from work done in our lab. And, I'll admit, it's tax time and I have to work on my contribution to the State of California and the Federal Government so this saves me a little time!

This example is based on a paper titled “Development of the Supply Chain Optimization and Planning for the Environment (SCOPE) Tool - Applied to Solar Energy,” which was presented at the IEEE International Symposium on Electronics and the Environment in 2008 in San Francisco. Copies of the full paper are available for download at http://escholarship.org/uc/item/9tq5x8fb.

The paper addresses the need for supply chain optimization and planning with the environment in mind, using reasonable metrics as part of the decision making process. The proposal is for a tool (called SCOPE as defined in the paper title) and the example applies the tool to solar panel manufacturing.

Renewable energy systems are being developed to satisfy three main goals: (1) provide reasonably priced energy (2) mitigate climate change (3) provide energy independence. The life-cycle environmental impact of energy supply can be reduced through research on materials, product design, manufacturing, and the supply chain; the focus here is on the supply chain because environmental tradeoffs at this level are generally not considered in new energy development.

The supply chain is defined as the set of suppliers required for a complete and successful final product, and the interconnecting network of these suppliers around the globe as detailed in previous postings in this series. The supply chain has been found to impact up to 25% of manufacturing costs in typical products, and preliminary studies indicate that environmental impacts may be similarly distributed. In this study we worked with SolFocus, Inc. (see http://www.solfocus.com/en/) a manufacturer of concentrator photovoltaic systems.

An initial assessment of SolFocus Inc. concentrator photovoltaic systems found transportation to be 10-20% of the lifecycle energy demand when panel transportation to installation site and glass transportation to assembly were included. Additionally, our research has shown that the strategy to minimize greenhouse gas emissions depends both on the electricity mix at the customer and transportation distances.

To do this correctly, environmental supply chain considerations can and should be incorporated early in the design process to ensure the greatest possible reduction in impact. Previous solar energy assessments, while thorough in their execution, have not focused on the climate change mitigation potential of a re-organized supply chain or installation location variables.

The SCOPE tool is a hybrid LCA tool and incorporates the following:

1. Electricity mix and resource differences throughout the supply chain since parts may originate from all over the globe, such as China, India, the U.S.A, and elsewhere. This approach parallels today's economic assessment for production, where manufacturing location decisions are influenced by economic decisions such as labor costs, energy costs, local regulations, resource availability, flexibility, and lead times. (But, the tool does not include these latter elements - yet.)

2. Transportation emissions and energy demand.

3. Electricity distribution and circularity. When determining the electricity that is offset by a new solar installation the "circularity" or distribution losses of electricity supply are usually not considered. Demand for electricity requires extra production to account for electricity that is lost in transport to consumers (distribution losses) or internally demanded by the energy sector (circularity).

The proposed SCOPE tool's basic architecture and underlying hybrid LCA methodology are presented in the paper and energy and greenhouse gas metrics are used by the tool to assess alternatives so check the paper for details. A case study of preliminary results for SolFocus Inc. is presented to establish the feasibility, applicability, and usefulness of SCOPE.

The metrics used are:

- energy payback time (EPBT) which indicates the number of years a technology must produce electricity, thus offsetting the use of primary energy from another electricity source, to offset the total energy required over its lifetime (including manufacturing, transport, installation, etc.)

- energy return on investment (EROI) calculated as the lifetime of the product divided by the EPBT EROI indicates how many MJ of primary energy are saved from consumption for every MJ of primary energy consumed.

- greenhouse gas payback time (GPBT), an analog of energy payback time for green house gas emission, and

- greenhouse gas return on investment (GROI). Similar to EROI, GROI indicates the GHG emissions prevented for every unit of GHG emitted encouraging the fastest route to reducing energy related greenhouse gas emissions.

To illustrate this approach an example is presented. In this collaborative project, we looked at a particular utility scale concentrator photovoltaic system SolFocus was developing. It is comprised of a solar panel, a "tracker" support structure that moves the panel to maintain incident solar exposure during the day, controller in the tracker, etc. Although the design and manufacture were still under development, available cost estimates and preliminary manufacturing data were available. A mockup of choices for producing a solar panel is shown in the figure below. The double boxes indicate one possible supply chain.

To illustrate the variability in energy and GHG metrics, four scenarios are considered: (1) no transportation over the life of the supply chain (2) transportation of goods across the SolFocus supply chain using the most efficient methods possible (truck, rail, water freight) (3) transportation using only air freight as a worst case scenario (4) same as 3 except installation in France rather than Phoenix with a DNI of 5.3 kWh/m2/day. DNI refers to "direct normal irradiance" and gives a measure of the direct solar energy available at a location. Not surprisingly, locations in sunnier locations (as in closer to the equator) are better for solar energy. Phoenix is considered a good site while France is considered marginal; DNI values can be even higher in Africa, Australia and other parts of the southwest United States. If you want to see what the DNI is for your location (in the US) see http://www.solarpanelsplus.com/solar-calculator/, for example.

For this assessment, installation is assumed to occur in Arizona, USA with a DNI of 6.9 kWh/m2/day. The panels are assembled in India, and most components come from China, India, Spain, or the U.S. The installation is utility scale and assumed to replace rather than supplement the local electricity mix; therefore production, circularity, and distribution of the current electricity mix are offset.

Although the SCOPE tool is still under development in LMAS, the application of the SCOPE methodology to this particular solar system, given available data, results in the supply chain tree shown in the figure below. Note that in the figure transportation is not yet included for every component.

The results of the analysis are shown in the table below and indicate the influence of transportation

in energy and GHG metrics. In reading the table, smaller values of payback time and impact of GHG/kWh are better! The GPBT shows the largest sensitivity to installation variations because it is directly proportional to the conversion factor for GHG per unit of electricity (recall last posting) and the circularity. Each metric is also sensitive to the type of transit used throughout the life-cycle as seen between scenarios 2 and 3. These results indicate the potential for supply chain and installation optimization using the SCOPE tool. The impact of variations in electricity mix at each supplier site on these metrics have not yet been explored.

Preliminary results for SolFocus concentrator systems across the range of scenarios tested indicate that the EPBT of SolFocus Panels can vary from 0.6 to 5 years depending on installation and manufacturing locations. The GPBT can vary from 1.1 to 49 years depending on the same factors, and is seen to be more greatly sensitive to location factors than an energy-based metric.

But, there is much to be done to complete such tools - specially for alternate energy applications. Energy use and greenhouse gas emission metrics are discussed here because energy use is relevant to the efficiency of solar technology and greenhouse gas emissions are relevant to climate change; however an additional key concern of climate change is water scarcity. Solar has the distinct advantage of not requiring water during its use-phase; therefore, the installation of solar to replace thermal power plants (which consume nontrivial amounts of water per kWh generated) in water scarce regions of the world could prevent water use and thermal pollution of waterways. Tradeoffs then emerge between EROI, GROI, and water scarcity that will require further investigation and understanding to design minimal impact manufacturing supply chains. Also, additional environmental metrics could be added as well, such as toxicity and acidification potential.

The tool does not currently account for travel by engineers, managers, and executives to work collaboratively, ensure quality control, and provide feedback. Also, estimation of error will be an important final step to an analysis using SCOPE. As inputs on costs, weights, distances, and more are entered into the tool, confidence intervals could be included that would result in a confidence interval on the final solution.

Finally, it is important to note that while SCOPE provides decision makers the ability to understand environmental tradeoffs between supplier location and transportation, decision makers must also consider lead times, flexibility, and quality of suppliers before making a decision; cost and operations considerations must eventually be included in SCOPE for it to be a viable and useful tool for decision makers (or, conversely, the tool must be integrated with existing software for estimating these elements as part of an integrated package.)

Although this example is more complex than the automotive example, there are obviously, still many layers to be considered. But, in this realistic example, the potential for assessing and optimizing (or at least choosing among several alternatives) the manufacturing supply chain for a real product is illustrated.

I hope you found this series interesting and that it gave some insight into green supply chains from a manufacturing perspective. For sure there will be more reference to green manufacturing supply chains in the future. It is one of the critical elements in green manufacturing.

Now ... back to my taxes!

Saturday, April 3, 2010

Greening the supply chain, Part 3

Part of a series

Our supply chain discussion started with some basic definitions of what is included in a supply chain from a manufacturing perspective, and then added what would be green elements for consideration. Last time I referred to Interface Carpets as a leader in sustainable business development because they have a corporate mission held from top to bottom, they have a set of measures to indicate where they are and what progress they are making toward eliminating waste, excess energy and materials use and intense recycling and reuse - and they track all this diligently. Continuous energy per unit of product reduction - the key ingredient in the equation for reducing impact. As you can tell, I think this company is "walking the walk" and not just "talking the talk."

Last time I also presented an example to illustrate the impact of supply chains and, in particular, energy mix and transportation related to a simple vehicle manufacturing global supply chain. One of the important determinants in the impact of that was that the CO2 emission will be different at each facility in the supply chain due to the different energy mixes associated with the electricity supplier in that location.

This is a serious consideration. Around the world, the energy mix by location can be dramatically different. We had discussed this in an earlier posting but let's look into this in more detail. The figure below with data from a number

Conversion factors for CO2 generated per kWh of electricity around the world

of sources shows the variation in the energy conversion factors from a number of countries around the world. The units in the table indicate the carbon intensity of electricity production (gCO2 per kWh of electricity (or 0.001 MTon/MWh). Smaller numbers indicate a lower impact per unit of energy. France is lowest due to the preponderance of nuclear power. Countries with a preponderance of coal-based electricity (such as China or India) will have a larger impact. As seen in the figure, the difference can be as high as 10 to 1 (if comparing India to France). (Data from: Source: MacKay, D., Sustainable Energy - without the hot air, UIT, Cambridge, 2009, pp. 335; China/India: http://www.ghgprotocol.org/calculation-tools/all-tools; accessed 7/9/09)

Let's consider a few manufacturing locations:

- France = 6.30 MTons CO2 (76 MWH x .083 MTon/MWh = 6.30 MTon)

- Japan = 36.70 MTons CO2

- USA = 46.60 MTons CO2

- India = 71.76 Mtons CO2

Same car … same process steps … big difference in impact! That's what was a big differentiator in the supply chain example of last time. If this impact/product at the manufacturing stage must at some future time be accounted for then where you make something will be even more important from the impact aspect and not just labor rates.

Now, these conversion factors are the weighted average for the country. Obviously, specially for large countries with variation in energy supply technology, these can differ within a country as well. Let's look at a prime example of this - the US. The figure below (click on it for detail) is a map of the United States

Conversion factors for CO2 generated per kWh of electricity in different regions of the US

with the conversion factors superimposed over regions of the country (and here, the conversion factors are 1/100th of the factors in the first figure; US average here is .606 (or would be 606 from the first figure) due to the source of the data). And, the source of the data in this figure is EIA, US DOE, “Updated State-Level Greenhouse Gas Emission Coefficients for Electricity Generation 1990-2000,” April 2002; and map: http://wordpress.org/support/topic/255876, accessed 6/27/09.

The US average CO2 impact to build the car was 46.6 MTons CO2. But, looking at building the same car in different parts of the country we see, again, tremendous differences:

- Washington (0.111) = 8.44 MTons CO2

- California (0.275) = 20.90 MTons CO2

- North Dakota (1.017) = 77.30 MTons CO2

- Kentucky (0.911) = 69.00 MTons CO2

Building our auto in areas with a heavy dependence on coal fired power plants for electricity gives the auto a large carbon footprint. The difference is as large as 3 or 4 to one (California vs North Dakota) or almost 10 to 1 (Washington vs North Dakota.) Of course, we don't build cars in Washington state or North Dakota. But we build them in Kentucky (Prius, for example) and used to build them in California at NUMMI in Fremont. So a comparison of the California vs Kentucky impact is rational - over 3 to 1 difference. So, if you buy an auto made in Kentucky and ship it to California for sale you might be looking at a substantial "impact penalty" compared to making and selling the auto in California.

As they say in the real estate business - location, location, location. Maybe the same advice applies (or will apply) for manufacturing and the supply chain!

If we would do the same sort of analysis, as we did in the example from last time, and consider more of the sustainability elements - social, environmental and economic impacts - the dominance of supply chain and the need to green that chain comes into perspective. We've put together a figure that captures

some of these impacts as shown below.

Global green supply chain considerations

Companies today get resources from many different places, convert that material in others, acquire and convert the materials from yet other places and, finally, assemble the products from components made them selves in one or more locations along with components from others from other places in the world.

I've tried to capture some of this complexity in the figure below (again, click on it for detail) which attempts to show, relative to many impacts and resources, the developing

Accumulation of product life cycle impacts

This is not at all trivial to keep track of these impacts let alone the source of all of these little bits and pieces. How this is done is still being developed and is of interest by a large number of multinational corporations.

But, to know the challenge is the first step. Then the metrics, software tools, analytical methodologies and, even, simple rules of thumb, can be developed and used to get a better picture of where we are and what progress we are making.